Solutions for Industry

Creating innovative solutions for Industry

Squishy Robotics’ solutions can help improve your company’s ROI. Industries and municipalities are quickly adopting Smart Cities and Industrial Internet of Things (IIoT) technologies to improve safety, efficiency, and productivity. Squishy Robotics can help integrate artificial intelligence (AI) and other machine learning that can help teams increase operational effectiveness, prioritize tasks and maintenance processes, and lead to better problem-solving solutions for manufacturing, transportation, petrochemical, and agriculture.

Impact Resistant

Repeated airdrops from drones, helicopters, and fixed-wing aircraft. Deployed from heights of up to 1,000 feet.

Drone Deployable

Fast robot deployment via popular commercial drone models means that data gathering is performed without risking human lives.

Improved Operational Awareness

Increase efficiency and reduce costs.

Drone Multiplier

A single drone can position several persistent, ground-level sensing robots, while keeping the drone available for continued aerial assessments.

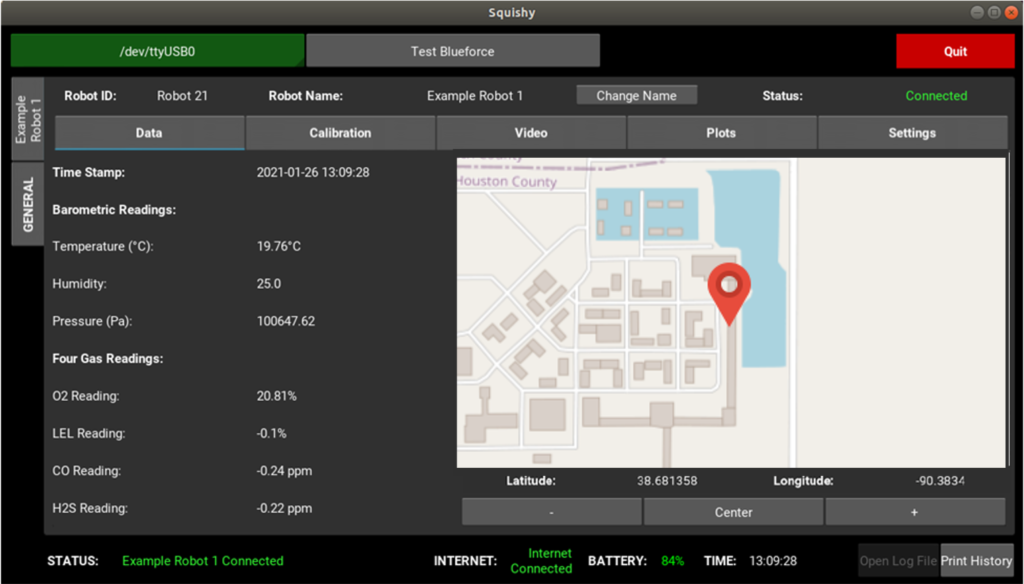

Customizable Sensor Platform

Customizable to meet your needs. Standard with a zoom camera, thermal camera, barometric sensors, and GPS. Optional: Optical Gas Imaging (OGI) thermal camera and NDIR methane sensors.

Data-driven Decision Making

Data when and where you need it to make informed decisions.

Modern inspection and emergency response operations are beginning to use Small Unmanned Aerial Systems (sUAS) as remote sensors to provide rapid improved situational awareness. Ground-based sensors are an integral component of overall situational awareness platforms, as they can provide longer-term persistent monitoring that aerial drones are unable to provide. Squishy Robotics provides an integrated aerial/ground solution for inspection, diagnostics and prognostics.

The Challenge

The Industrial Internet of Things has increased the number of sensors permanently installed in industrial plants. Yet there will be gaps in coverage due to broken sensors or sparce density in very large plants, such as in the petrochemical industry. Critical decisions depend on these sensors, but what should be done if there are anomalous readings or an indication of a hazardous situation that might require shutting down the plant or evacuating the local community? Should they put people in danger to take more accurate or localized sensor readings?

The Solution

Squishy Robotics optimizes the deployment of emergency sensors spatially over time. AI techniques (e.g., Long Short-Term Memory neural networks, Random forests) identify regions where sensors would be most valued without requiring humans to enter the potentially dangerous area. The cost function for optimization considers costs of false-positive and false-negative errors. Expected Value of Information (EVI) is used to identify the most valuable type and location of physical sensors to be deployed to increase the decision-analytic value of a sensor network. This case study using data from the Tennessee Eastman process dataset of a chemical plant displayed in OSIsoft (now part of AVEVA) or Blueforce interfaces.

Do you care about the environment? Are you a thought leader from industry looking for more effective solutions for methane detection and remediation?

The recent report by the United Nations’ Intergovernmental Panel on Climate Change (IPCC) makes it abundantly clear that immediate action is required to mitigate the worst effects of climate change. Methane is the second most common greenhouse gas, accounting for approximately 20 percent of global emissions.

In the Oil & Gas industry, methane (CH4) emissions are particularly hard to detect and localize. Emissions are highly transient and often occur in remote locations (abandoned/underperforming wells, tank farms, gas compression sites, and pipelines). Methane emissions typically have low flow rates of pure methane that quickly saturate typical handheld sensors if measured at the point of emission. Measuring methane emissions from afar is almost impossible because the gas quickly disperses in the air. Due to the multiplicity of production sites compared to the number of refineries, these sites usually do not have a full-time operator, increasing the risk that a methane emission will go unnoticed. Methane emissions may come from identifiable locations (e.g., tank vents, pneumatic controls, or regulatorily approved venting) while unplanned emissions may occur at a diverse set of locations (e.g., leaks from piping, values, or seals). Identifying these emissions requires improved tracking and analysis that can effectively provide early detection and trigger interventions for priority remediation.

Our goal is to not only help oil and gas companies reduce unwanted methane emissions, but also use our data analytics to prioritize remediation actions and use for sustainability certifications.

Squishy Robotics is launching a study to develop an innovative solution for increasing the number of methane inspections and the quality of recorded measurement data by using a hierarchical approach involving optimal rapid placement methods, multimodal sensing strategies, multiagent collaboration, and data analytics. See some of our prior publications in AI, sensor fusion and sensor placement.

We are looking to interview innovators and Oil & Gas industry experts to better understand the problems, challenges, and pain points with current solutions. If you are interested in joining us in this study, please contact Professor Alice M. Agogino at agogino@berkley.edu.

Field Testing & Demonstrations

Overturned Tanker Training with LACoFD

Squishy Robotics engineers joined the Los Angeles County Fire Department during a hazardous materials (HazMat) training scenario at the Del Valle Regional Training Center “HazMat City.” Deployed via drone airdrops, our sensor robots provided visual and 4-gas sensor data to the incident command center during a simulated tanker truck leak.